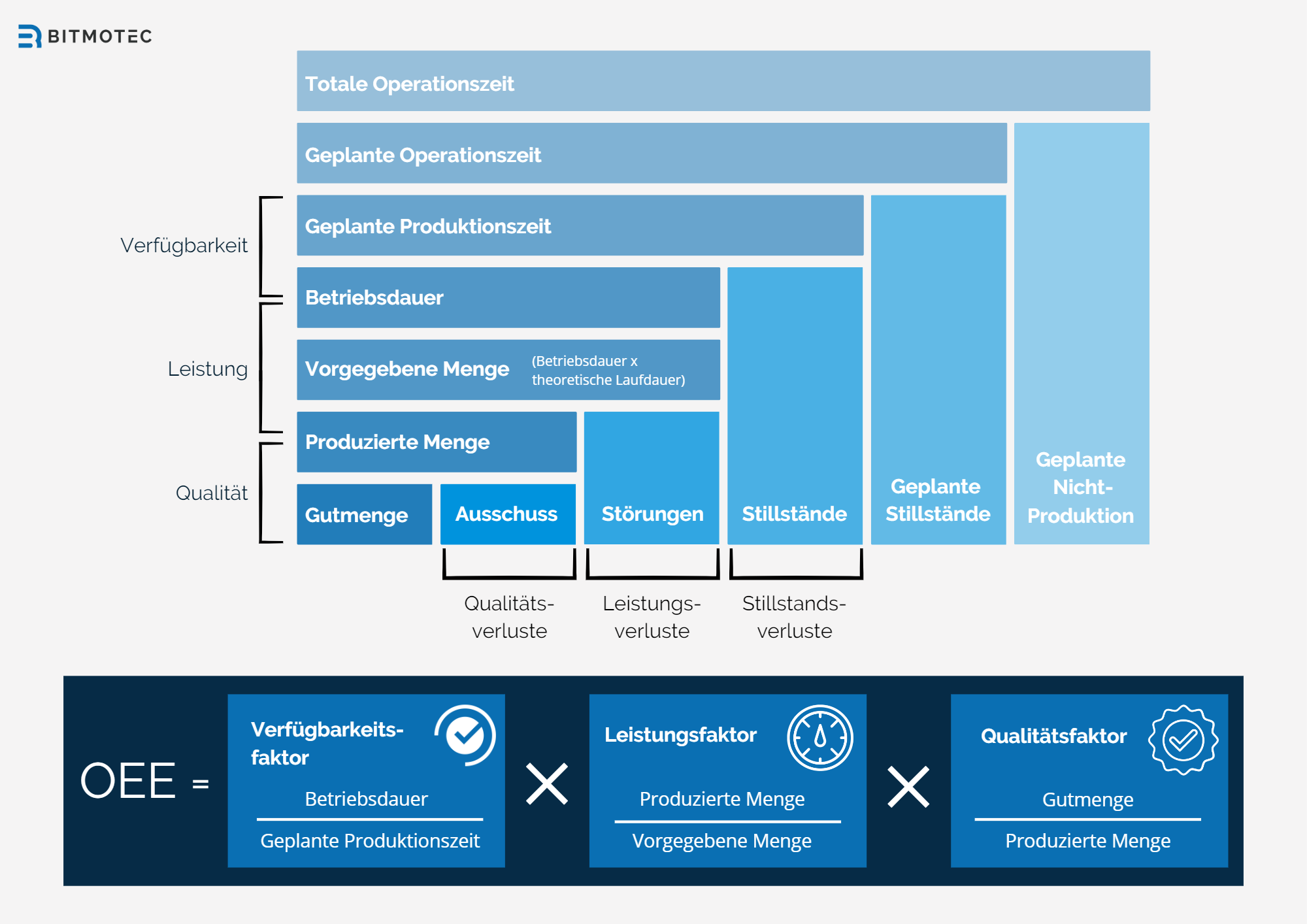

OEE Main Components

Overall Equipment Effectiveness (OEE) is a metric used in companies to measure the efficiency of a machine or plant. The KPI is made up of the three main OEE components : availability, performance and quality rate. Each of these components has an impact on the overall efficiency of the machine or plant. A high OEE means that the machine or equipment is operating effectively and therefore meets the specified performance targets.

Availability

The availability factor (or machine availability or plant availability) is one of the main components of OEE and measures the time that a plant is actually available for production in relation to the planned production time. To calculate the availability factor, subtract the downtime from the planned production time and divide the result by the planned production time:

Availability = (Planned Production Time – Downtime) / Planned Production Time

Downtimes can be caused, for example, by machine failures, maintenance work or set-up times. Accordingly, a high availability factor means that the plant has actually used a large part of the planned production time.

Performance

The performance factor, also known as the speed factor, measures the actual production speed of a plant compared to its maximum possible speed. The performance factor is calculated by multiplying the units produced by the ideal cycle time and dividing the result by the actual operating time:

Performance = (Units Produced × Ideal Cycle Time) / Actual Uptime

Consequently, a high performance factor indicates that the system is operating close to its maximum possible speed. Therefore, if the performance factor is low, it means that there is room for improvement to increase production speed.

Quality Rate

Quality Score is the third major component of OEE and measures the proportion of high-quality units produced during the production period. The Quality Score is calculated by dividing the high-quality units by the total units produced:

Quality = High Quality Units / Units Produced

A high quality score indicates that a large proportion of the units produced meet the quality standards. Therefore, a low quality score indicates that there are product quality issues that need to be addressed.

The combination of the three main OEE components of availability, performance and quality makes it possible to calculate overall equipment effectiveness. A high OEE indicates that a plant is operating efficiently and making optimal use of its capacity. By continuously monitoring and improving these factors, companies can optimize their production processes and increase their competitiveness.

More content from Bitmotec on the topic of OEE: