OEE Software and OEE Dashboard

In the modern manufacturing industry, OEE software and an OEE dashboard play an increasingly important role in optimizing production and increasing efficiency. In this article, you will learn everything about how it works, the benefits, and the selection criteria.

The OEE for all machines.

Arrange a demo appointment now to coordinate your test operation.

What is OEE software?

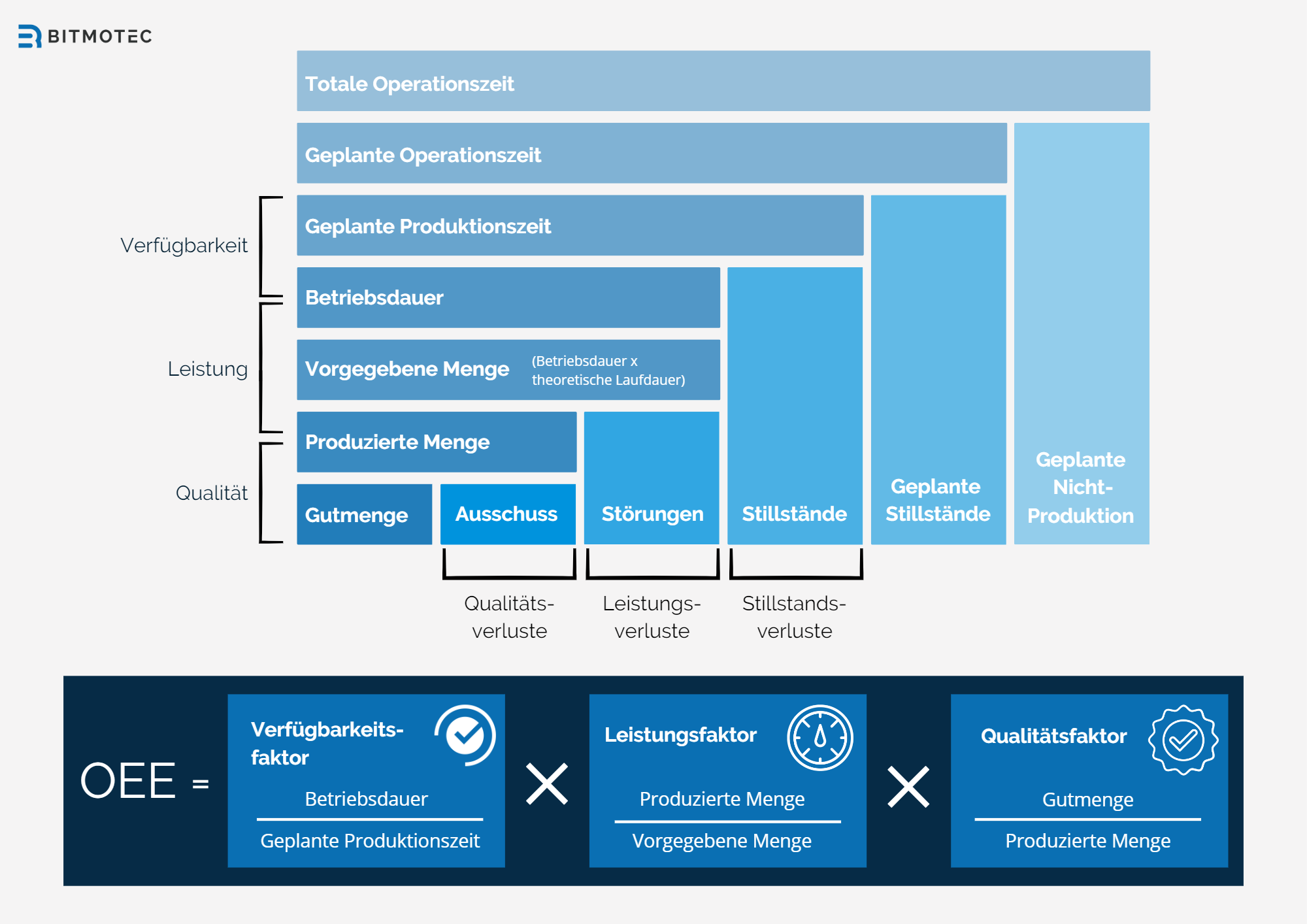

OEE stands for “Overall Equipment Effectiveness” and is used to measure and improve the efficiency of production plants and machines. The software calculates the OEE value, which is made up of availability, performance and quality, and thus provides a comprehensive overview of the productivity of a plant.

Companies use OEE software to identify bottlenecks in production , uncover potential for improvement, and increase the efficiency of their plants.

Benefits of OEE Software

OEE software helps improve productivity and profitability by calculating and visualizing OEE values in real time. This enables companies to react quickly to emerging problems and effectively optimize production processes.

Automated OEE calculations and real-time data ensure precise and continuous monitoring of plant performance. This leads to a reduction in production costs and an increase in product quality. In addition, companies can identify weaknesses in production, plan resources better and make targeted investments in improvement measures.

The use of software also helps to promote collaboration between different departments in the company. This leads to a shared responsibility for optimizing production processes and a better understanding of the requirements and challenges the company faces. Overall, OEE software enables data-driven decision-making that has a positive impact on business development and growth.

Types of OEE Software

On-Premises OEE Software: In this variant, the software is installed and operated locally on the company’s servers. This can provide greater control over the data and IT infrastructure, but it also requires more maintenance.

Cloud-based: The software is hosted on external servers and used via the Internet. This allows for easy access from anywhere and reduces maintenance. However, companies must pay attention to data protection and security.

Differences between desktop and mobile OEE apps: Desktop apps are installed on the computer, while mobile apps run on smartphones or tablets. Mobile apps have the advantage of being able to be used from anywhere, while desktop apps often offer more extensive features.

Selection Criteria for OEE Software

When choosing OEE software, you should pay attention to the following aspects:

- Functionalities: The software should provide all the necessary functions to measure and improve the OEE value.

- Usability: A user-friendly interface is important for employees to use the software efficiently.

- The OEE software should be easy to integrate into existing systems and processes.

- Support: Good customer support is crucial to get help quickly if you have any problems or questions.

Implementation of OEE software

Steps to implement OEE software in the company:

- Needs analysis: Identification of the requirements and objectives to be achieved.

- Selection of the right OEE software: Decision for a solution based on the above selection criteria.

- Integration into existing systems: Adaptation of the software to the existing IT infrastructure and production processes.

- Employee training: Training staff on how to use the software to ensure effective use.

- Continuous improvement: Regular review and adaptation of the software in order to continuously optimize production efficiency.

Best Practices for a successful implementation:

- Collaboration between IT and production: Close collaboration between both departments is critical to a smooth implementation.

- Testing phase: A test phase should be carried out before full implementation in order to identify and fix potential problems at an early stage.

- Change management: The introduction of new technologies can lead to resistance. Effective change management helps to increase employee acceptance.

OEE Dashboard

An OEE dashboard is a visual representation of the data that makes it possible to monitor production performance at a glance. It shows key performance indicators such as availability, performance and quality, as well as the overall OEE value.

OEE dashboards help improve productivity by making it easier to identify bottlenecks and inefficiencies and enable data-driven decision-making.

Challenges

Possible problems when using OEE software and OEE dashboards:

- Lack of data quality: Inaccurate or incomplete data can lead to incorrect OEE calculations.

- Resistance in the company: Employees may be skeptical about the introduction of new technologies and reject their use.

How to overcome these challenges:

- Ensure data quality: Careful monitoring and maintenance of data acquisition systems are necessary to enable accurate OEE calculations.

- Change management: Communication of the benefits of OEE software and OEE dashboards, training and support in use help to reduce resistance and increase acceptance in the company.

Result

In summary, the implementation of OEE software and OEE dashboards is an effective tool to increase productivity and efficiency in manufacturing companies. Through careful selection and implementation, companies can benefit from the advantages of this technology and increase their competitiveness on the market.

Outlook for the future: With advancing digitalization and the further development of artificial intelligence and machine learning, OEE software and OEE dashboards will provide even more precise analyses and optimization suggestions in the future in order to make production processes even more efficient.