Implementing OEE in industry

Overall Equipment Effectiveness (OEE) is a key metric in the manufacturing industry that helps measure and optimize the performance and efficiency of production equipment. In this article, we will show you how to implement OEE and the role of technology in improving production efficiency.

The OEE for all machines.

Arrange a demo appointment now to coordinate your test operation.

Brief Introduction

Definition

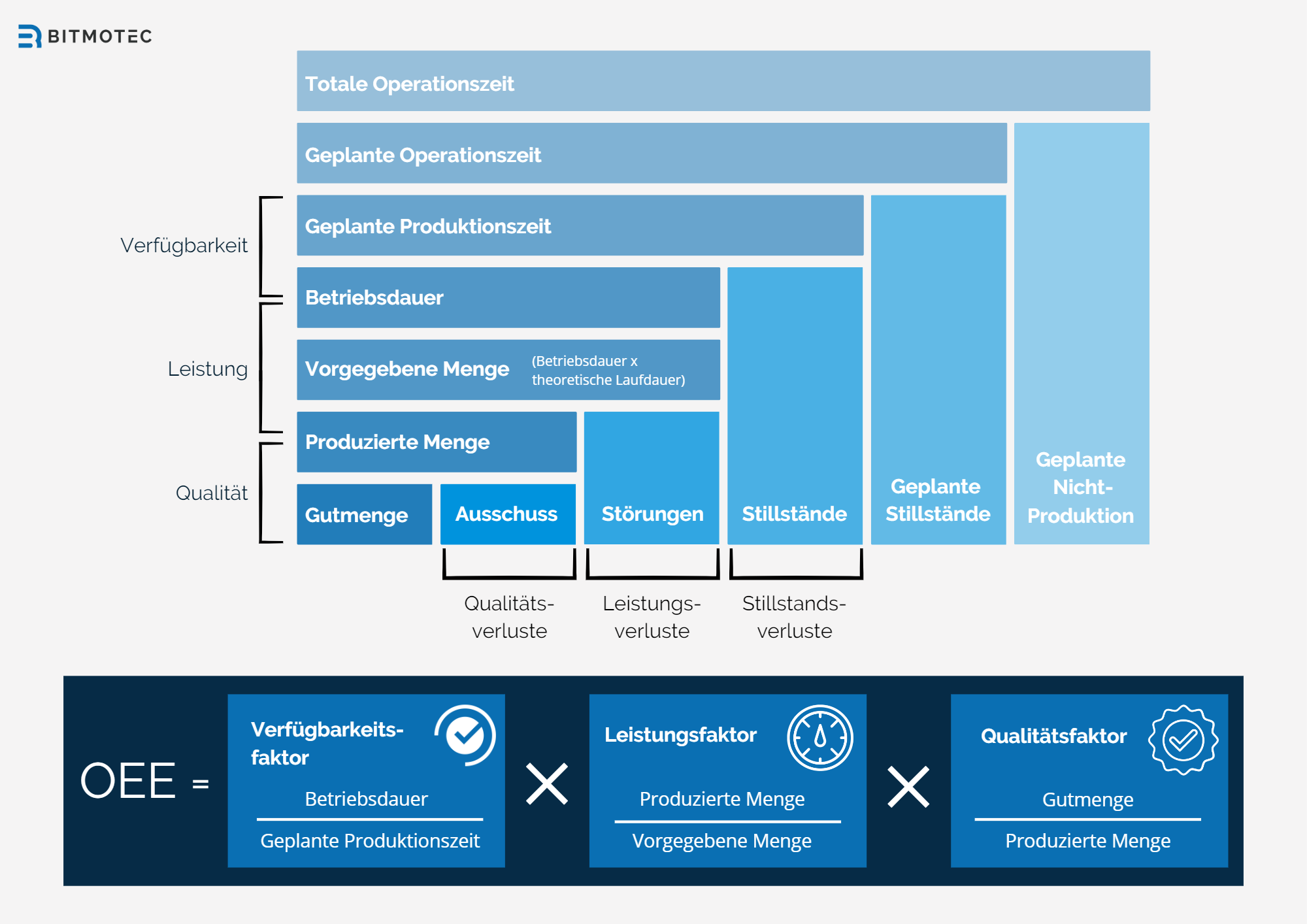

OEE is a key figure that represents the actual performance of a machine or plant in relation to its theoretical maximum performance. It is expressed as a percentage and takes into account three main components: availability, performance and quality.

Key figure and main components with calculation

The OEE calculation is based on the three main components:

- Availability: The proportion of the planned uptime in which the machine is actually running.

- Achievement: The actual production speed in relation to the maximum possible speed.

- Quality: The proportion of defect-free products in total production.

OEE is calculated by multiplying availability, performance and quality: OEE = availability x performance x quality.

Implementing OEE in industrial processes

Implementing OEE in production processes requires detailed planning and preparation to achieve the best possible benefit.

Important Considerations Before Implementation

Before you implement OEE in your company, you should consider the following points:

- Objective: Define clear objectives for implementing OEE to motivate your employees and make progress measurable.

- Make sure all employees are aware of the concept and importance of OEE.

- Select appropriate measurement and data acquisition methods.

- Prepare your IT infrastructure and systems to integrate OEE data.

- Resources: Make sure you have sufficient resources to perform OEE measurement and analysis, including qualified personnel, technical equipment, and software.

Step-by-step implementation guide

The implementation can be done in the following steps:

- Training: Train your employees to understand the OEE metric, its meaning and how it is calculated.

- Collect baseline data for availability, performance, and quality.

- OEE calculation: Calculate the metric based on the data collected.

- Analysis and identification of areas for improvement: Analyze the results to identify areas of efficiency losses and derive improvement actions.

- Develop a detailed action plan to realize the identified areas for improvement.

- Implementation of improvement measures: Implement the identified measures to increase the OEE ratio and monitor their success.

- Continuous improvement process (CIP): Repeat this process regularly to achieve continuous improvements and optimize your overall equipment effectiveness.

- Communicate results and successes within the organization to drive employee engagement and support continuous improvement.

Common Challenges and How to Overcome Them

There may be some challenges during implementation, such as:

- Employee resistance: Communicate openly about the benefits of OEE measurement and actively involve your employees in its implementation.

- Insufficient data collection: Make sure you have sufficient and accurate data to correctly calculate the OEE metric.

- Complex production processes: Tailor the measurement to the specific needs of your business and take into account all relevant factors.

To successfully overcome these challenges, you should:

- Ensure open communication and training for employees to promote acceptance and understanding of OEE.

- Ensure accuracy and consistency of data collection by standardizing processes and using appropriate measurement technology.

- Examine investments in IT infrastructure and systems to enable efficient data collection, analysis, and integration.

Through careful planning and implementation, you can overcome these challenges and achieve a successful implementation in your organization. By addressing your employees’ concerns, collecting accurate data, and tailoring OEE measurement to your specific production processes, you can reap the benefits of the OEE metric and sustainably increase your productivity and efficiency.

Using Technology to Improve OEE

The use of modern technology can significantly support OEE measurement and optimization.

The Role of Automation and Sensors

Automation and sensor technology can help capture data in real-time and minimize human error in data collection. In addition, they enable precise monitoring and control of production processes.

Examples of Technology Applications to Improve OEE

- Industrial IoT platforms and sensors for continuous monitoring and analysis of machine data.

- Intelligent maintenance systems that can detect potential machine failures at an early stage and initiate maintenance measures to reduce unplanned downtime.

- Advanced analytics and machine learning to identify areas for improvement and optimize processes in real time.

- Digital production planning and control that enables efficient use of resources and adaptation to changing production requirements.

New technologies and the future of OEE measurement

New technologies such as artificial intelligence, big data and blockchain offer further opportunities to improve OEE measurement and optimization. They can help to better understand complex relationships in production processes, make data-driven decisions and optimize collaboration within the supply chain.

Conclusion – A Call to Action for Businesses

The implementation of OEE is an essential step towards increasing production efficiency and competitiveness in the manufacturing industry. Companies should systematically adopt OEE and use the use of modern technologies to achieve continuous improvement. It is important to involve employees and focus on data-driven decisions.